1. Introduction: Why material selection matters under extreme conditions

In many engineering and industrial environments — such as high temperature, high wear, corrosive fluids, or abrasive particulate exposure — the choice of metal or alloy can make or break component performance. A wrong material leads to premature failure, frequent replacement, and high operating cost.

This article compares three major material classes — hard alloys (cemented carbides), high-temperature / superalloys, and wear-resistant alloys — and offers guidance on how to choose among them (or combine them) depending on your service conditions.

2. Overview of the three material classes

2.1 Hard Alloys (Cemented Carbides)

- Hard alloys (also called cemented carbides) are composite materials combining carbide phases (e.g. WC, TiC, TaC, etc.) with a metal binder (commonly cobalt or nickel).

- They offer extremely high hardness, excellent wear resistance, and good thermal stability. Even at elevated temperatures (several hundred °C), hardness and wear resistance remain stable.

- Their weaknesses include lower toughness (more brittle) compared to many superalloys, and susceptibility to chipping under heavy shock or vibration.

Use cases: cutting tools, wear parts, tooling inserts, components in abrasive service.

- Superalloys (nickel-base, cobalt-base, iron-base high-performance alloys) are designed to maintain strength, creep resistance, and corrosion/oxidation stability at high fractions of their melting point.

- They typically have excellent toughness and ductility compared to cemented carbides, which gives them better ability under dynamic loads or thermal cycling.

- Their downside is that their hardness / wear resistance is generally lower than cemented carbides; in heavy abrasive wear, superalloys often need surface coatings or reinforcement.

Use cases: turbine blades, furnace internals, exhaust components, hot-section parts.

- This is a broader, somewhat overlapping category, comprising alloys specifically designed (or treated) to resist wear under sliding, impact, erosion, abrasion, or corrosion.

- They may be steel-based, Ni-based, Co-based, or specialized alloy blends, sometimes with hard particles (carbides) embedded, or with surface hardening / coatings.

- Their performance is intermediate: better toughness / ductility than cemented carbides, and better wear resistance than “standard” alloys if well designed.

Use cases: valves, pump parts, liners, sliding surfaces, abrasion zones.

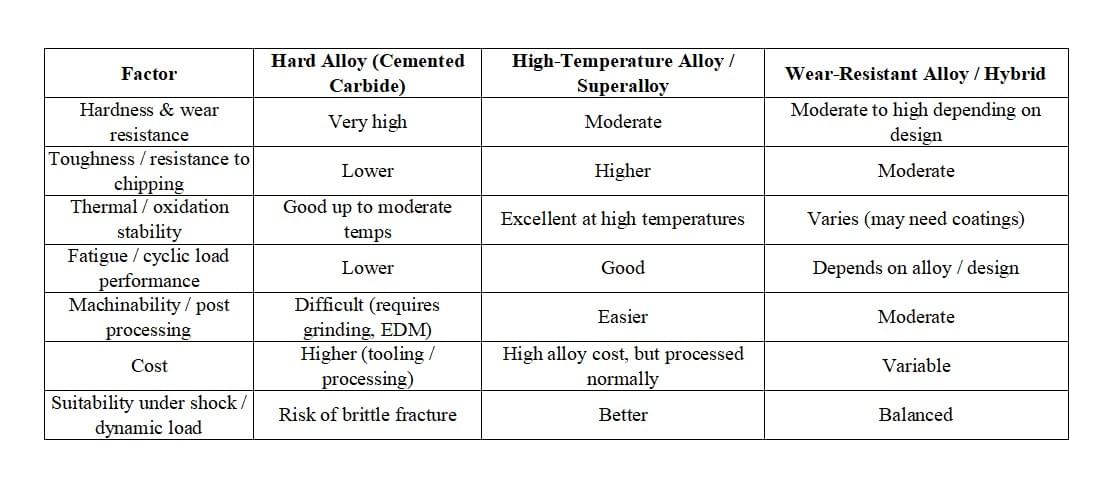

3. Key performance factors to compare

When selecting among these material types (or in hybrid / composite designs), these are the main performance factors to weigh:

Also consider: environmental corrosion (oxidation, chemical exposure), temperature gradients, thermal cycling, and cost / maintainability.

Moreover, in sliding or metal-to-metal wear, cobalt-based alloys often show superior resistance under high loads in absence of lubrication.

4. Application-oriented decision guide

Below are some typical scenarios and choosing suggestions.

4.1 High-temperature, high stress applications (e.g. turbine, furnace)

Use a superalloy when sustained mechanical strength, creep resistance, and oxidation stability are critical. In many cases, if wear is also an issue, combine a superalloy core with a wear-resistant surface treatment or plugin of carbide parts.

4.2 Abrasive, high wear / erosion environments

Here, cemented carbides shine. Their superior hardness and wear resistance make them ideal in abrasive wear zones. But care must be taken to mitigate brittleness (e.g. avoid impact loading, provide support, combine with ductile substrate).

4.3 Mixed / transitional conditions

In many real-world parts, one region undergoes high wear while other regions must endure stress or fatigue. In such cases, design hybrid components: wear zones using carbide inserts or overlays, backing material of superalloy or wear-resistant alloy.

4.4 Importance of geometry, load path, and design

Material choice alone doesn’t guarantee success. Proper design (thickness, support, transitions, stress relief) is essential. In high-wear zones, allow repairability or replacement of wear inserts.

Suppose a mining pump impeller is exposed to mineral slurry (abrasive) and also elevated temperature (say 300-400 °C). A purely superalloy impeller may erode rapidly, while a full carbide impeller may fracture under hydraulic shock. A balanced solution: use superalloy for the backbone and hydraulic surfaces, and embed hard-alloy (cemented carbide) linings or wear rings in the zones of highest wear.

You, as a supplier (Panda Carbide), can offer such hybrid designs, conduct finite element / wear simulations, and deliver pre-assembled wear inserts matched to your alloys.

6. Tips & best practices when selecting material

- Get accurate service environment data — temperature, load, sliding speed, abrasive particle size, fluid chemistry.

- Consider safety factor / service life targets — don’t just optimize for lowest cost material: design for robustness.

- Plan for inspectability / replaceability — wear parts should be accessible or modular.

- Use lab testing / prototypes — wear tests, thermal cycling tests, fatigue tests.

- Leverage your supplier’s knowledge — good suppliers can help you choose or even simulate.

7. Summary & call to action

Selecting the right material under extreme conditions is never one-size-fits-all. Cemented carbides (hard alloys) dominate in wear-critical zones; high-temperature superalloys bring strength and oxidation stability; wear-resistant alloys occupy the middle ground — and smart hybrid designs often deliver the best balance.

At Panda Carbide, we specialize in advanced cemented carbide / hard alloy products, custom wear inserts, hybrid component solutions, and technical support for material selection. If you'd like help assessing your application, matching materials, or sourcing samples, feel free to [contact us] or request a free technical consultation / sample kit / wear simulation report.

Panda Carbide-More Than Tough!

Panda Carbide Technology CO., LTD.